Stepper Motors

Stepper motors divide each full rotation into a number of equally sized steps. Also known as step or stepping motors, these 2-phase brushless DC motors offer quick, precise load positioning and exceptional holding torque at any of these incremental steps. Each step represents 1.8°, or 200 steps per revolution. When using a microstepping drive, each 1.8° step can be broken into even smaller increments to achieve nearly servo-like positioning performance—without the need for complex feedback devices or a closed-loop control system.

Comprehensive Product Line

SDT stepper motors are used in applications from life-sustaining medical devices to high-throughput manufacturing lines to explosive oil and gas production environments. With decades of stepper design experience, we have developed a wide range of motor series to suit the needs of OEMs in virtually any motion-critical industry—whether the application requires a high value-to-cost ratio, premium performance in extreme environments, or specialized capabilities and fit.

Highest Performance

All Stepper motors lose usable torque as running speed increases. This is known as torque roll-off. SDT minimizes torque roll-off through superior optimization of electromagnetic design. Several Stepper families also offer Enhanced technology. Enhanced motors include rare earth magnet added in the motor stator – which results in torque increases up to 25% across the entire speed range.

Co-Engineered Modifications and Custom Prototyping

SDT offers a huge selection of standard sizes, constructions, windings and options including custom leads, shafts and connectors—plus thousands of standard modifications to help you achieve a perfect fit for your application. Moreover, we can collaborate with you to co-engineer features such as shaft and seal modifications, specialized windings, application-specific cables and connectors, integrated encoders and more. We can even deliver fully custom solutions, with minimal additional lead time and investment, thanks to our rapid prototyping, optimized manufacturing and global supply footprint.

Proven Reliability and Support

Our advanced hybrid stepper motors incorporate large bearings, high-voltage insulation, large rotor diameters, tight air gap tolerances, and high-energy magnets and windings that other manufacturers don’t offer. These rugged design features have been proven time and again in the field, ensuring a long, reliable service life that we back with a two-year warranty. And when you need technical assistance, you can always count on our self-service design and product selection tools, engineer-to-engineer expertise, and in-region product design, manufacturing and support. The SD Series is designed to provide exceptional value, versatility and ease of use. Among the most powerful stepper motors available, they deliver high torque in a compact package and are available in a wide range of frame sizes, constructions, and optional modifications. SD has an extremely competitive market lead time and is backed by CE certifications. Our 2-phase hybrid stepper motor range offers sizes from 20 to 110mm with 0,9° or 1,8° step angle options.

With SDT’s unmatched motion expertise, you can achieve higher speeds while maintaining all the torque you need. Your machine can be smaller, faster, more energy-efficient, and more affordable to build and operate—all measurable advantages over machines powered by competitors’ motors. .

Stepper Motors

|

|

|

|

| SD20 | SD34 | SD35 | SD42 |

|---|

|

|

|

|

| SD57 | SD60 | SD86 | SD90 |

|---|

|

Series |

NEMA |

Current/Phase |

Holding Torque |

Size |

|---|---|---|---|---|

|

SD20 |

NEMA 8 |

0.6-0.8 |

0.02-0.036 |

20 |

|

SD34 |

NEMA11 |

0.67-1.5 |

0.052-2.4 |

28 |

|

SD35 |

NEMA14 |

0.28-1.0 |

0.2-0.37 |

35 |

|

SD42 |

NEMA 17 |

0.31-1.68 |

0.14-29.3 |

42 |

|

SD57 |

NEMA 23 |

1-3 |

0.44-40 |

56.4 |

|

SD60 |

NEMA 24 |

1-3 |

0.44-40 |

60 |

|

SD86 |

NEMA 34 |

5.5-6.2 |

5.5-6.2 |

85 |

|

SD90 |

- |

5.5-8 |

5.5-8 |

90 |

| Custom Design |

Our Stepper motors & drives are designed to be easily and cost effectively customized for the specific OEM application. If the best solution is “clean sheet” approach, SDT is ready to help, from concept through production. |

|||

IP65 Rated

SDT's NEMA 14, 17, 23, 24, and 34 stepper motors with high IP ratings are specially designed for for Harsh or Humid Environments, and to meets splash-Proof requirements, featuring special sealing for longer life at the rear end and between stator and flanges, a front shaft contact seal, sealed-lamination housing, leak-proof cable entry, and so on.

|

| IP65 Rated |

|---|

Encoders

SDT stepper motors can be delivered with an optional encoder system. The magnetic encoders that are used are highly robust, which makes them an ideal solution for use in harsh environments

Holding brakes

Brakes are used wherever moving mass must be stopped in a defined manner and whenever braking torque must be maintained if the power supply fails. Here again with their holding brakes, SDT offers yet another cost-effective and high-performance solution.

|

| Holding brakes |

|---|

|

|

|

|

| C17 | C23 | C34 | C80 |

|---|

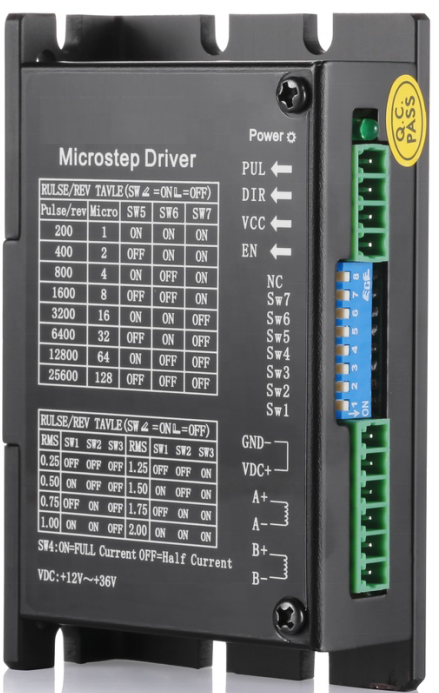

| Modal | Command Source | Voltage (VDC) | Current (A, Peak) | Input Frequency (KHz, Max) | Logical Voltage (VDC) |

|---|---|---|---|---|---|

| C17 |

PUL & DIR, CW & CCW |

20-50 |

3.0 |

500 |

5 or 24 |

| C23 |

PUL & DIR, CW & CCW |

20-50 |

7.0 |

500 |

5 or 24 |

| C34 |

PUL & DIR, CW & CCW |

18-80VAC or 30-110VDC |

8.0 |

500 |

5 or 24 |

| C380 |

PUL & DIR |

70-130 VAC or 127 VDC |

8.0 |

200 or 500 |

5 or 24 |

Custom Design |

Our Stepper Drives are designed to be easily and cost effectively customized for the specific OEM application. If the best solution is “clean sheet” approach, SDT is ready to help, from concept through production. |

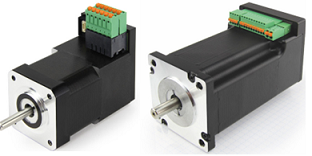

Stepper Motors with Controllers

SDT offers integrated stepper motors in three sizes and with a holding torque of up to 9.3 Nm. Due to their high torque at low speeds, closed-loop stepper motors are especially well-suited for direct drives. Smart stepper motor with integrated controller and encoder. Space-saving all-in-one servo system that simplifies installation. Flange sizes: NEMA 17, 23, and 34.

- Precise position, speed and torque control

- Magnetic single-turn absolute encoder or battery-free multi-turn absolute encoder

- Digital and analogue inputs, digital outputs

- Integrated temperature monitoring to prevent overload

- Smooth running, no resonances.

- Controlled by fieldbus, clock & direction or analog/digital inputs

- Easy to parameterize via CANopen or USB

- Simple programming with the Plug & Drive Studio

- Closed loop with singleturn absolute encoder

- High precision and smooth running

- Motors with USB interface are particularly suited for control via IO (clock & direction, analog)

Matching gearboxes can be added via the configurator after selecting a motor.

Gearboxes

SDT's series hybrid stepper gear motor offers a wide range of gear ratios to fulfil your project needs. The transmission series gearboxes (includes spur and planetary) have been strictly tested to ensure long life and maximum efficiency. They are low-cost solutions and can perfectly meet your needs of motion or automation control. Besides, high precision gearhead, custom motor winding and gearhead specs are also available.

Stepper Motors with Spur Gearboxes

Modification Is Our Standard

SDT can evaluate further customization as needed. Contact our Customer Support team with your specific requirements. So whether you need something from our vast inventory of stock products, need to develop a configured or fully custom product (stepper motors, stepper drivers, Gearboxes), or just need help developing an idea, contact us today.

Support and Services

As with all SDT products, customers can count on the support they need to optimize motor/drive selection, sizing, setup and performance. Worldwide product availability and SDT’s proven heritage ensure long-term project success.